Parameters

| Brinell scale | HBW2.5/62.5, HBW2.5/187.5, HBW5/62.5, HBW5/125, HBW5/250, HBW5/750, HBW10/100, HBW10/250, HBW10/500, HBW10/1000, HBW10/1500, HBW10/3000. |

| Test force | 62.5kgf(612.9N),100kgf(980.7N), 125kgf(1226N), 187.5kgf(1839N), 250kgf(2452N),

500kgf(4903N), 750kgf(7355N), 1000kgf(8907N), 1500kgf(14710N), 3000kgf(29420N). |

| Load control | Automatic (loading/dwell/unloading) |

| Maximum test height | 220mm |

| Depth of throat | 130mm |

| Minimum measuring unit | 0.005mm |

| Dwell time | 1-99 sec |

| Measuring range | 8-650HBW |

| Hardness value read | 20X |

| Executive standard | EN, ISO 6507, EN ISO 6506, ASTM E-384, ASTM E-10-08, ASTM E-384 |

| Indenter-upper wall distance | 55mm (can increase the pressure from the indenter to the upper wall by customizing the indenter) |

| Hardness reading | After the indentation is measured through the Brinell Microscope, the length of the indentation is directly input by the button to obtain the hardness value. |

|

Data output |

Built-in printer, print content: test conditions, number of measurements, average, maximum, minimum, maximum error, etc. |

| Power requirements | AC200V±10%, 50Hz |

| Dimensions (mm) | 520*210*745mm |

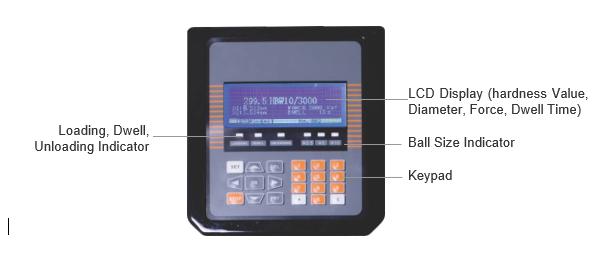

| Display | LCD Screen |

| Host weight | About 120kg |

Accessories

| Name | Quantity | Name | Quantity |

| Brinell microscope | 1 No. | 2.5, 5, 10mm diameter carbide ball indenter | 1 each |

| Standard hardness block | 2 Nos. | Large, medium and V-type test Tables | 1 each |

| Power Cable | 1 No. | Instruction manual | 1 No. |

| Fuse | 1 No. | Dust cover | 1 No. |